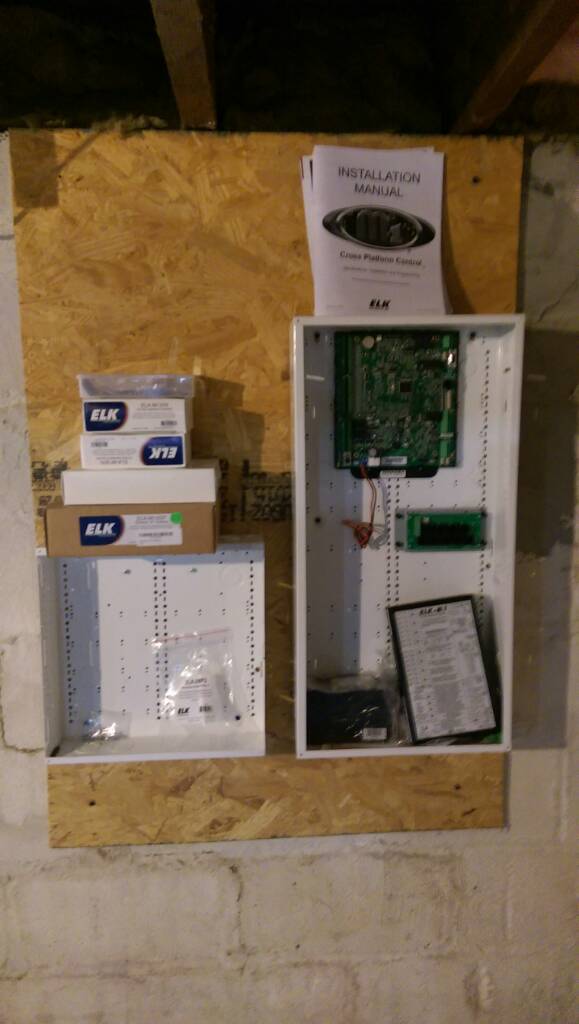

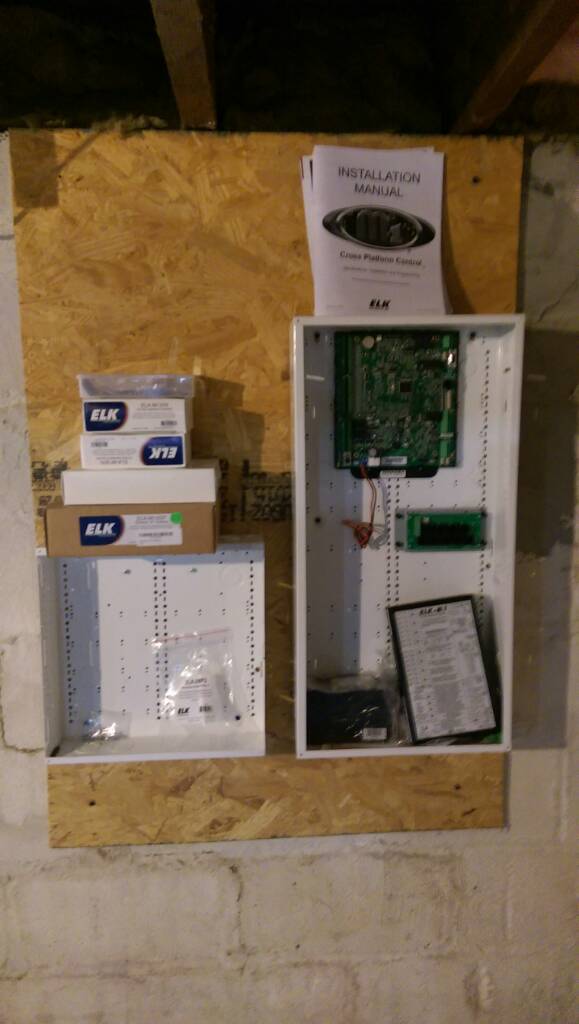

Hey folks, I've been lurking for a few years now, managed to pickup some Elk components under the guise of a security system during a whole house renovation project this past year (It literally took me a year.. ) and I'm finally ready to land some wires. I was hoping that I could impose upon some of you for tips and or advice on laying out panel(s). I'm a bit OCD, so this will end up looking more like a work of art than a security/ha panel, but I dont want to cut anything until I have a plan. I'm thinking about terminating all of the field wiring on terminal strips in the smaller panel and then pulling jumpers across to the inputs in the larger panel. Or perhaps using the smaller panel for batteries (I think I only need one.) and only using terminal strips for power distribution to field devices within the main panel. I'm a bit fond of that slotted raceway, I suspect it would make my OCD quite happy. I have two panels, a handful of boards, and lots of wires. Elk M1g with two XIN, XSP, EXP, DBH, and an SA DB9 Interface Module. Home runs to; 18x Windows 9x Motion 9x Doors 8x Glass Breaks 2x Keypads 2x Interior Speakers.

...v Sent from my HTC One_M8 using Tapatalk

...v Sent from my HTC One_M8 using Tapatalk