Hello All,

I'm trying to monitor my GE Symphony II Generator to determine when it's ON or OFF.

i've got an ELK with a zone already wired to the "Fault" output on the generator, however I would prefer to trigger simply when the generator is running.

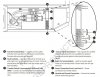

I attached the wiring diagram.

Here is the link page 25 shows the connections i'm assuming i'll need to use. It's currently connected to the fault N/O contacts.

If anyone can advise how to monitor the status that would be great. I should note that it does come with a wireless monitor which lights an LED up, however I do not want to rely on that, and prefer the hard-wire directly to the Generator.

Thank you

I'm trying to monitor my GE Symphony II Generator to determine when it's ON or OFF.

i've got an ELK with a zone already wired to the "Fault" output on the generator, however I would prefer to trigger simply when the generator is running.

I attached the wiring diagram.

Here is the link page 25 shows the connections i'm assuming i'll need to use. It's currently connected to the fault N/O contacts.

If anyone can advise how to monitor the status that would be great. I should note that it does come with a wireless monitor which lights an LED up, however I do not want to rely on that, and prefer the hard-wire directly to the Generator.

Thank you