well, I hope there is no problem taking it from where I am. I like to leave the humidity bus all to its self. I am buying one of Ross's i/o boards for the 2.3.8, but not the one with the vr.

with this default of 0x84 = 131, you are setting it to differential & measuring the voltage between ai0 and ai1, not between ai0 and gnd. also to continuous. when you said you used default, I thought you were still referring to the data rate, but you slowed it there, from default, so I wondered if there was a reason

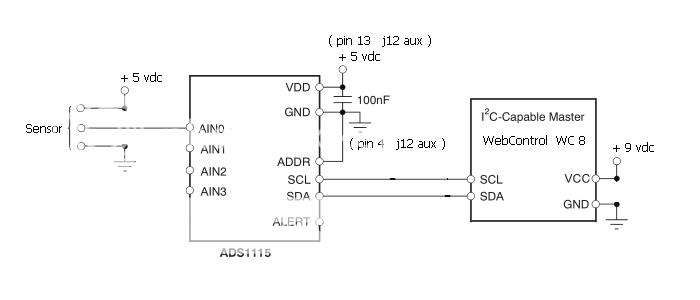

I went out to add another 100nf cap, and while I did that I also shortened every lead I could. I have read now that i2c likes to have its slaves close at hand, and your mention of noise and jitter induced me to shorten even more, the i2c bus pair between the wc8 and the little protoboard where the adc is. It's about 6" now. I also replaced several jumpers with shortest versions.

When I came back in, voila, lovely data. quickly wrote code to see all four inputs twinkling their values in the first four VARs. success!

being curious and stubborn, I went back out and pulled the extra cap. all FFFF. further fiddling showed that the new cap, or both, gives data; the original cap gives 65535. It's a tantalum, new, and was polarized properly, so no idea there. doesn't seem to have been any issue with the wiring, only the cap.

took the opportunity to test other modes, single read and continuous both work fine. the data rate at the default 128 sps also works. and those delays don't need to be so long. with no delay, in singleread, all the reads are the same low value; setting it to 10 is enough for the reads to stabilize at their meaningful steady values.

here's some working plc, for singleread and pga +/- 6v on ai0:

I2CWRITE 1 0 144

I2CWRITE 0 0 1

I2CWRITE 0 0 193

I2CWRITE 0 1 131

DELAY 10

I2CWRITE 1 0 144

I2CWRITE 0 1 0

I2CWRITE 1 0 145

I2CREAD 0 0 RAM11

I2CREAD 0 1 RAM10

SET VAR1 RAM1L

this gives 4836 +/- 1 for ai0, which is wired to 1.1vdc. reading the other inputs, ai1 is at 5vdc and reads 65534 rarely dropping momentarily to 63553, ai2 is grounded and reads ~2975 +/- 5, and ai3 is floating and reads ~2775 +/- 5. the time variation in the values is quite low and tolerable. there's still some work to do playing with the scaling but I can see that it is basically working.

so this is good, I can get at least four of these sensors into the wc8, that's going to help immensely, thank you. I still need to test with the additional boards, to make sure it can handle more at once.

now I'm on to the 16 bit i/o MCP23017