If anyone is interested will show you my solution.

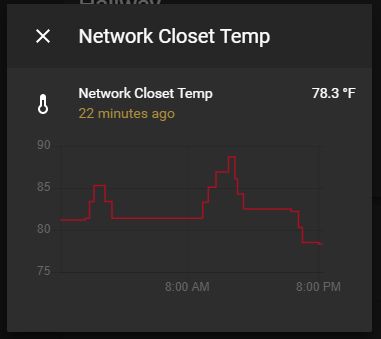

First, I got forced into the solution. I added a computer to the closet, and shot the door and watched the temperatures. It was running mid 80's before the computer, but rose quickly to the high 80's without. I was going to let it go until mid-90's, thinking that was reasonably safe -- my router started crashing about 88 degrees. And the router was 3' lower than the temperature sensor. I guess home use stuff is just not made very well (Linksys WRT1900ACS).

The first hump is yesterday when I started to test it but decided to go to bed and opened the door. The right hump is where things started crashing. I do not know how much hotter it would have gotten. The significant drop is my turning the AC down while working (it was not running much as not very hot out).

This does not show the max temp with my solution running, will see that over night.

Here's what I did: Home depot for duckboard; they had none so got a sheet of foam insulation ($14). I used about 5% of it, quite a waste, could probably have used a piece of sheetrock as well. I made it the size to hold 2 computer fans.

I taped the fans together and put a 12v socket on it. I had a bunch of old 12v bricks, and the fans were left over from a computer build, so essentially free but pretty cheap if I had to buy.

The hardest part was cutting a hole in the wall that matched up on each side. I cut one then tried to mark the other, in retrospect it might have been easier to take a long drill and drill each corner (though whether I could go straight enough is a good question). Fortunately duct tape (the metal kind) covers a lot of sins.

Now the fans:

To mount the fans I just put four toothpicks on each side, holding them in place (angled away so they would not vibrate into the blades). Looks silly but took all of a minute and no cost.

Net result outside the closet:

In this case I have the vanes angled so you cannot easily see into it from the ground. In the closet I reversed it so I could easily see if both fans are running:

Silent, at least compared to the switch and router much less computer.

While I put this note together and did some cleanup it has been maybe an hour and the closet is about 3 degrees above ambient and appears to be leveling off, though it may go a bit higher.

Incidentally, at about 2 watts each it seems pointless to control the fans, I plan to have them run 24x7. In a computer such fans usually last many years, hoping that will be true here also.

The grills were about $6 each so about $30 in pieces and parts invested, and a few hours (some of which waiting for touchup paint to dry -- I cut the hole with a sabre saw that left a lot of marks on the wall).

Hopefully that will fix things.

Would the hole with no fans have been adequate, depending on convection? Maybe, but the low temperature at which the router failed concerned me.

Did I need the duct as opposed to just blowing into the wall? Probably not, but when I decided to use foam I realized how simple it was to build, and the fans probably are more efficient in a relatively sealed tunnel.

This was my second choice, by the way. it looks like it has a fan and thermostat for relatively cheap ($50). And it is pretty. But my cheap concoction is pretty enough I think, from the outside.

https://www.amazon.com/gp/product/B00QFWLGPU/ref=ox_sc_saved_title_5?smid=A2AW0W4FKP16S5&psc=1

(In case amazon link breaks it is an AC Infinity Airplate T3)

Linwood