I admit I'm not much of an electronics guy, so what am I missing here?

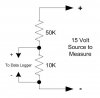

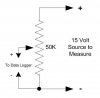

I am getting a data logger that logs DC volts in the 0 to 2.5vdc range. I want to monitor a generator battery with it because I'm having intermittent problems with battery's voltage. The battery is a typical group 26 auto battery. I'm assuming that the battery voltage will never go above 15vdc, so I want 0-15vdc to be reduced to 0-2.5vdc for the logger. The manufacturer pointed me to this FAQ entry on their website to find out how to build a voltage divider. Essentially, the formula it has says I need a 50k ohm resistor in series to drop the voltage from 15 to 2.5.

I wanted to test things before hooking up the logger, so I got a 50k ohm potentiometer. I tested the battery voltage with a multimeter first, and it showed 13.44vdc. I then clipped the pot in series between the battery's positive post and the multimeter's positive lead, and connected the negative multimeter lead to the battery's negative post. When I turned the pot, the voltage only varied from 13.44 to 13.37. I tried it with a 100k ohm pot and that resulted in double the reduction -- from 13.44 to 13.30. So according to those numbers, I would need something like a 10 megaohm resistor to drop 15v to 2.5v.

So can someone school me on this?

Thanks,

Ira

I am getting a data logger that logs DC volts in the 0 to 2.5vdc range. I want to monitor a generator battery with it because I'm having intermittent problems with battery's voltage. The battery is a typical group 26 auto battery. I'm assuming that the battery voltage will never go above 15vdc, so I want 0-15vdc to be reduced to 0-2.5vdc for the logger. The manufacturer pointed me to this FAQ entry on their website to find out how to build a voltage divider. Essentially, the formula it has says I need a 50k ohm resistor in series to drop the voltage from 15 to 2.5.

I wanted to test things before hooking up the logger, so I got a 50k ohm potentiometer. I tested the battery voltage with a multimeter first, and it showed 13.44vdc. I then clipped the pot in series between the battery's positive post and the multimeter's positive lead, and connected the negative multimeter lead to the battery's negative post. When I turned the pot, the voltage only varied from 13.44 to 13.37. I tried it with a 100k ohm pot and that resulted in double the reduction -- from 13.44 to 13.30. So according to those numbers, I would need something like a 10 megaohm resistor to drop 15v to 2.5v.

So can someone school me on this?

Thanks,

Ira