Automate said:Agreed, I don't think this should be a big issue. Even the most simple power supply is going to have some amount of inductive or capacitive filtering.

Remember we are talking about AC so at 60Hz the input voltage is going to zero every 8.33ms anyway.

10ms is just over half of a single sine wave. Not much in the big scheme of things

While it is true that the AC voltage goes to zero every 8.3ms, that's not what is important. What is important is the amount of energy being transferred when the voltage is not zero.

The UPS spec allows for a drop out of up to 10ms, which is a bit over 60% of one complete AC cycle. So the power supply would have to have that much stored energy to fill in the gap. That may not seem like much, but it actually is.

A typical Raspberry Pi draws about 1.0A at 5V, or 5 Watts of power. During a 10ms drop out, that would be 0.05 Joules of energy.

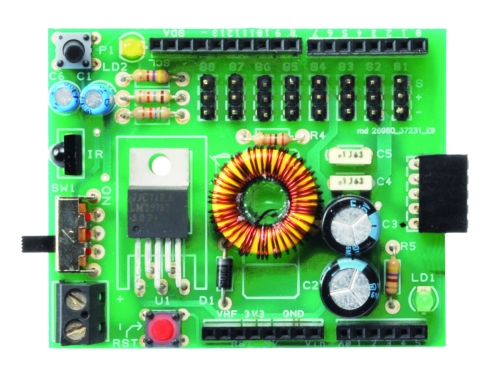

A quick, back of the envelope calculation says you would need a 4000 uF capacitor to store that much energy.

That's a pretty big capacitor in terms of physical size, and would take up a large fraction of the space available in a small, wall wart type of USB charger. I doubt that any of them have anything close to enough capacitance to sustain the output during a 10ms power drop.