LinuxPoobah

Member

I'm about to move into my new home. It is around 12,000 sq ft and has 146 HAI switches in it.

I did most of the low voltage wiring myself (uggh). I home ran everything into a cold storage room in the basement plus I have lots of empty conduit runs as well.

The LV wire I have run includes:

* CAT 6 data (computer hook ups, security panel, touch screens, thermostats, plus some extra thrown in for good measure)

* CAT6 and RG6 quad shield to "TV/media locations" for distributed satellite and ethernet for popcorn hour, PS3s, etc.

* CAT6 & RG6 runs for 13 security cameras

* Alarm wire (windows, doors, motion sensor in every room, glass break sensors)

* Water leak sensor wire

* RCA for audio sources

* Many speaker runs for whole home audio and intercom (wired for Russound Compoint)

The cold storage room I ran everything into has 4 separate power circuits (two 15 AMP, and two 20 AMP). The cold storage (in the basement) also has a 2" conduit up into the attic space.

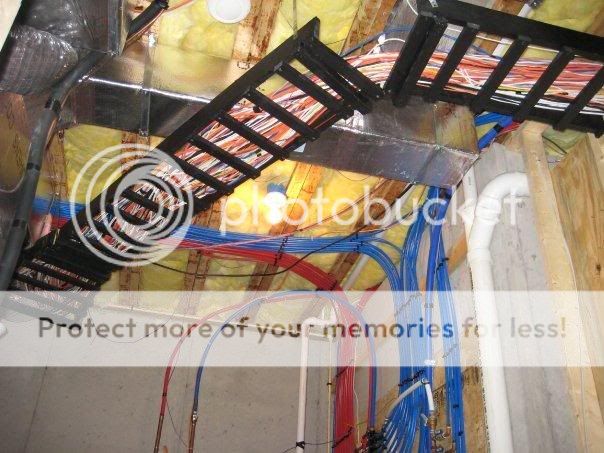

What I ended up with looks like this (the wires are mostly labeled):

I had a small 4x6 wall framed up (no drywall) with the anticipation of mounting enclosures and panels.

How should I go about terminating all this wire?

Suggestions and tips greatly appreciated.

I did most of the low voltage wiring myself (uggh). I home ran everything into a cold storage room in the basement plus I have lots of empty conduit runs as well.

The LV wire I have run includes:

* CAT 6 data (computer hook ups, security panel, touch screens, thermostats, plus some extra thrown in for good measure)

* CAT6 and RG6 quad shield to "TV/media locations" for distributed satellite and ethernet for popcorn hour, PS3s, etc.

* CAT6 & RG6 runs for 13 security cameras

* Alarm wire (windows, doors, motion sensor in every room, glass break sensors)

* Water leak sensor wire

* RCA for audio sources

* Many speaker runs for whole home audio and intercom (wired for Russound Compoint)

The cold storage room I ran everything into has 4 separate power circuits (two 15 AMP, and two 20 AMP). The cold storage (in the basement) also has a 2" conduit up into the attic space.

What I ended up with looks like this (the wires are mostly labeled):

I had a small 4x6 wall framed up (no drywall) with the anticipation of mounting enclosures and panels.

How should I go about terminating all this wire?

Suggestions and tips greatly appreciated.