86turbodsl

Active Member

12,000 square ft house and you're DIY on low voltage wiring????? Anyone else thinking WTF?

I just got done building a 2900 ft house with 6000 ft of cat 5 and I know what it cost me. I can't even imagine what that would cost.

It ended up being more DIY work than I initially imagined (with several "WTF am I doing" moments), but it worked out. My career started out doing Adds/Moves/Changes on a Harris 20/20 phone system along with IT system administration work so pulling wire and using a punch down tool are something I'm comfortable with. I wanted a home automation system that I could 100% manage myself and be as simple or as complex as I wanted. It should work intuitively and fail gracefully.

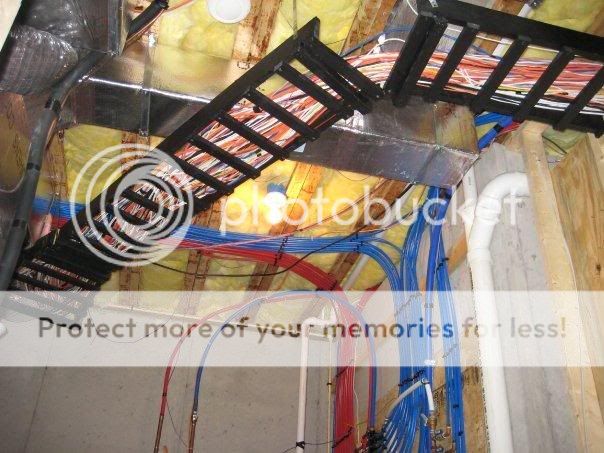

The biggest stress was getting it done fast enough so that I didn't delay the insulator sub and then the drywallers.

If I remember right, I think I ended up with about 23,000 ft of LV wire (CAT6, RG6 QUADSHIELD, 14 gauge speaker wire, alarm wire, etc) . This home has quite a few other "big numbers" associated with it (425 yards of concrete, 100 squares of shingles, 18 HVAC zones, 20,000 ft of radiant heat pex pipe (including the heated 310' driveway), 240 recessed can light fixtures, 1,100 ft crown molding, etc, etc). I'm sure it sets no records though.

I plan on using Linux and open source tools as much as possible. The home deserves at much, it was made possible by Linux.

Wow. Sounds like about 1.5M worth of stuff. (not prying). If you don't mind, what do you do regarding Linux? I'm a big fan, having used it on and off since about 95 and Redhat 5.0.

BTW, good job on the radiant. I put it in our house and love it. But not the heated driveway. That's HUGE money to run.

Got any pics of the build? Love to see your wiring closet.