NeverDie

Senior Member

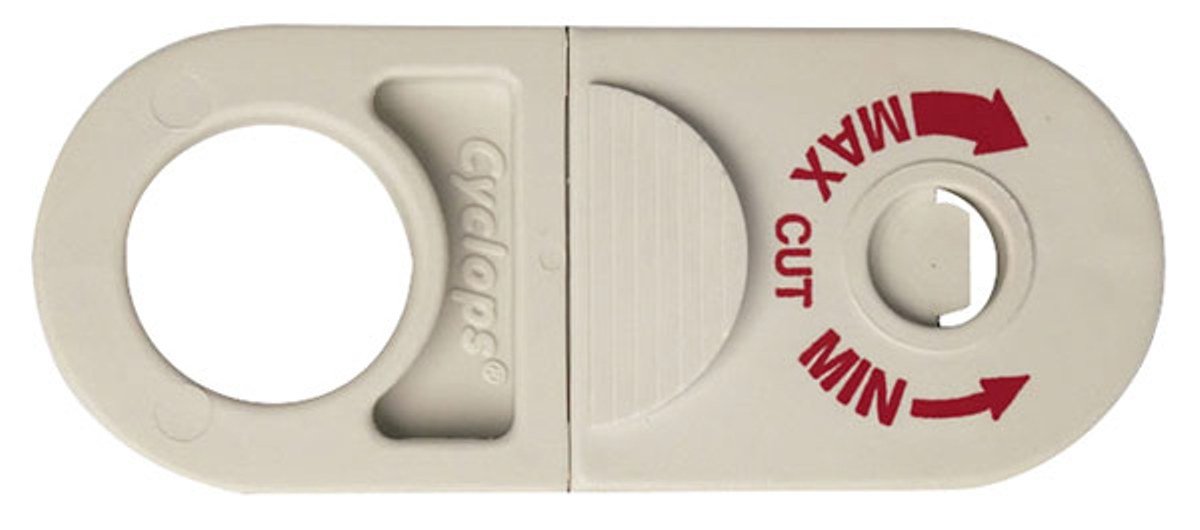

It sounds like you 1. installed 4-5 snapjacks, 2. later removed all the snapjacks you had installed, 3. never used snapjacks again, and 4. preferred crimping the ends over snapjacks. Does that sum it up?pete_c said:This related to the initial "wiring" of the main floor of the two story home using these and single keystone wall plates. I was in a learning DIY mode at the time so I purchased the snapjacks in bulk as they were reasonably priced at the time. It actually was the 4-5 that were initially installed then removed when I learned to be able to just crimp the ends. I figured though that I had already spent the monies on spools of a 1000 feet of cat5e (went to color coding for a time); might as well look granularly at the work stuff. Thinking at the time; new banks in old buildings...following around the cable guys and asked them to show me exactly the how and what they were doing with their tools et al type of stuff (sort of being a PITA for my own knowledge base)....well they were my projects anyways; so I got a bit granular with it....kind of always been like that....I sat in some classes for welders and learned a bit about using plasma welding machines from some "guru's"....I was so amazed at their skill level (also took a short class with underwater welders - kind of short lifespan with these guys)....remember asking them to build me a support structure for a piece of computer stuff that weighed in at probably over 2000 lbs ...it took some 15 minutes to build my little widget but a whole day to move it as I had to knock down masonary walls to get it where I wanted it....

The parts are due to arrive in the next few hours, and it sounds like I'll be better off crimping rather than snapjacking....