Clark Martin

New Member

I'm new to this forum and to 1-wire. I was perusing the old messages and in one about waterproofing sensors Plasti-Dip was suggested. I've seen this type of product around in the past but couldn't find it in the hardware store today. I did however find Liquid Electrical Tape.

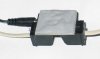

I bought some and have dipped one DS1820 so far. I only did it today so it's not fully cured and therefore I haven't tested it out. But I wanted to bring it up and point out a couple of advantages over Plasti-Dip.

First, it's made for insulating 120VAC wiring so it should have essentially no electrical impact, specifically resistance. I don't know if other products do or don't but something made for dipping tools may well a poor electrical characteristic since it doesn't matter in the original application.

Second, I think it's quite a bit thinner than Plasti-Dip. It certainly worked it's way in and around all the wires. I used twisted pair I pulled out of a commercial CAT-5 cable. This wire is stranded and so doesn't have the usually springiness of solid CAT-5. Later I'm going to try dipping the last 6-12 inches of the wire to seal it up, cable like. I want to place the probe in liquids and I figure it's better to not get the pair in contact with the liquid. More to keep water from wicking up the pair than worry that the wire isn't watertight.

I also daubed some Liquid Electrical Tape into the open end of the RJ-11 connector on the other end of the probe. It filled the opening and even wicked it's way up into the two unused wire holes. But it isn't leaking out anywhere. I also daubed it around the wire as it enters the connector providing something of a strain relief.

I bought some and have dipped one DS1820 so far. I only did it today so it's not fully cured and therefore I haven't tested it out. But I wanted to bring it up and point out a couple of advantages over Plasti-Dip.

First, it's made for insulating 120VAC wiring so it should have essentially no electrical impact, specifically resistance. I don't know if other products do or don't but something made for dipping tools may well a poor electrical characteristic since it doesn't matter in the original application.

Second, I think it's quite a bit thinner than Plasti-Dip. It certainly worked it's way in and around all the wires. I used twisted pair I pulled out of a commercial CAT-5 cable. This wire is stranded and so doesn't have the usually springiness of solid CAT-5. Later I'm going to try dipping the last 6-12 inches of the wire to seal it up, cable like. I want to place the probe in liquids and I figure it's better to not get the pair in contact with the liquid. More to keep water from wicking up the pair than worry that the wire isn't watertight.

I also daubed some Liquid Electrical Tape into the open end of the RJ-11 connector on the other end of the probe. It filled the opening and even wicked it's way up into the two unused wire holes. But it isn't leaking out anywhere. I also daubed it around the wire as it enters the connector providing something of a strain relief.