beelzerob

Senior Member

Fear is finally setting in. I've now inspected the installed windows in the house and I'm scratching my head where I'm going to put the contact sensors. The windows are the Andersen 200 double hung tilt/wash series.

I think there's no hope at all of a concealed sensor, specifically on the lower sash. There's very little broad flat edge on any of them.

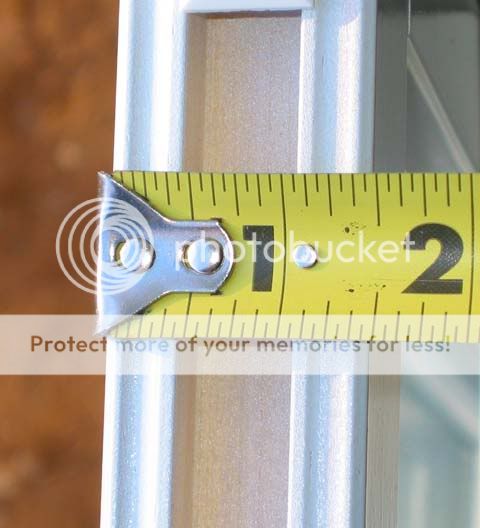

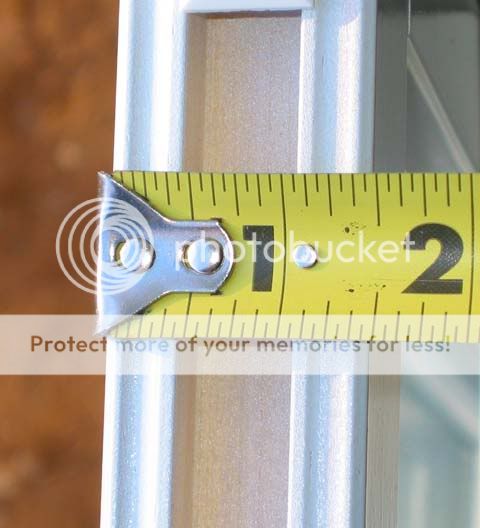

This is the bottom edge of the bottom sash:

The thickest smooth part is barely 3/8". Aren't the smallest concealed sensor magnets more than that? The other issue is that when the window is closed, there's still a decent gap between the bottom of the sash and the frame:

About 1/4". You can also see that the area where the contact sensor matching the magnet would go in the frame, and it looks like it might be even less than 3/8".

So, I considered the top part of the bottom sash...it has a thicker area (on the side of course, since nothing could be mounted on the top and be concealed).

So there appears to be plenty of room there for a small magnet. However....in the frame where that part of the sash would be, there's a bunch of fur-type stuff. Not exactly drilling heaven.

I'm not sure how I feel about trying to drill through that...the fur is probably there for a reason.

Now with the top sash, I have another delimna...there's absolutely NO place for a surface mount. Part of the reason is that when the bottom sash is opened all the way up, it leaves this:

I know it LOOKS like a gap, but in reality, it has completely covered the top sash. So any surface mounted anything will be cleanly scraped off everytime we open the bottom sash. I suppose I can artificially limit how far the bottom sash can open....

But maybe I won't have to...the top sash seems to have more and better potential for putting in a concealed sensor on the top. Here's the top of the sash:

Almost 3/4"!

And the top of the frame where that seats is about the same size (ladybug for scale...and because they're EVERYWHERE):

So I'm thinking at this point I'd probably have to go surface mount on the bottom sash and concealed on the top. I'd really rather go concealed on the bottom too.

Does anyone see any better option or something that might fit in these constraints and work well?

MUCH LATER....

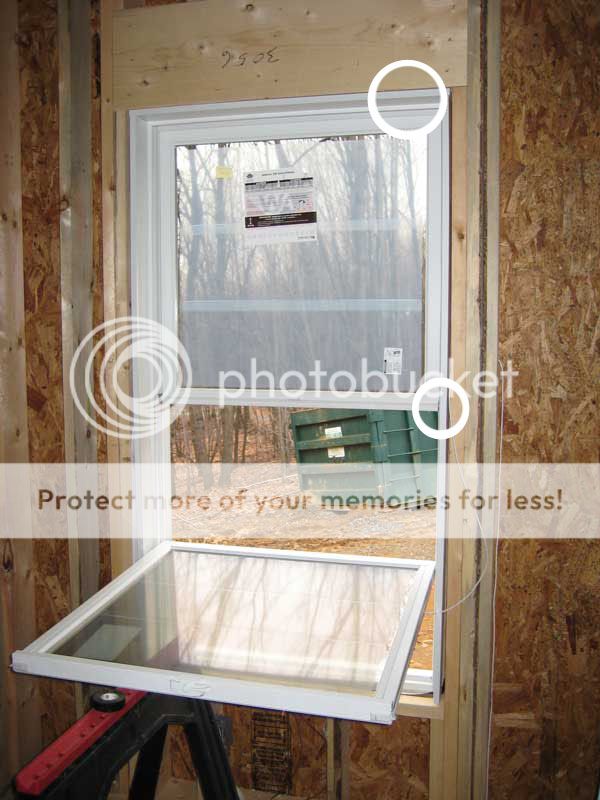

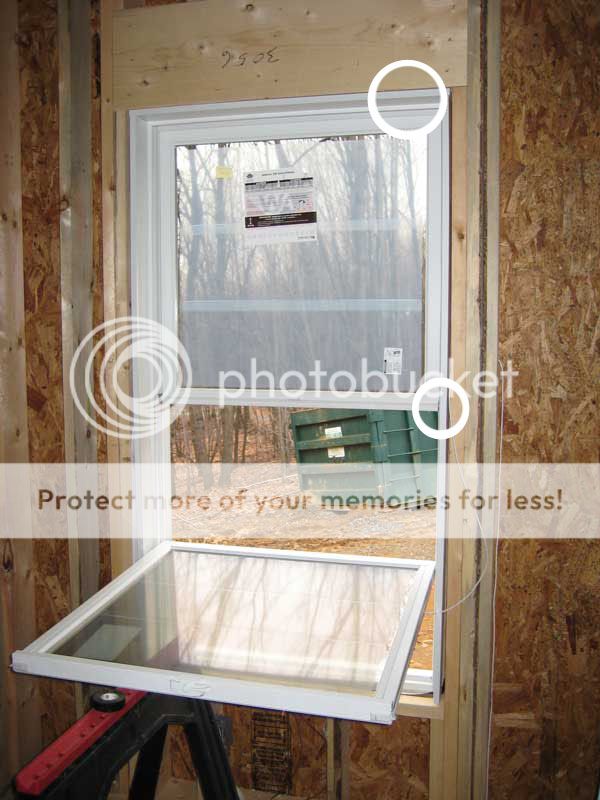

Well, here is how I finally did it:

The circles indicate where the sensors and magnets were put. I drilled into the frame surrounding the window just below the middle of the window, where the sashes meet. In this pic, the bottom sash is unlatched and tilted out so I can work on it.

The first thing I did was the top sash because that's where the end of the wire was....on the 2nd floor, I had to do the bottom sash first. It didn't really matter.

First was the prep...

I needed to make sure that the magnet was lined up with where the sensor went, so I put a piece of tape on the sash at the spot the magnet was going to go, because that was kind of picky. Then I closed the sash, and put another piece of tape on the frame at the same spot. So, as long as I drill the hole right next to the tape into the frame, and then glue the magnet right next to the tape on the sash, then they'll certainly be close enough to work together.

I then drilled the hole using the 3/8" bit. The bit had a very sharp bit, so I can basically press it into the vinyl (they were vinyl clad wood windows) so that the bit didn't walk at all. Once the hole was drilled, I used a spare piece of wire, twisted into a little loop, and I pushed it up into the hole. I then took my specially made tool (it's a leftover piece of metal from when I installed our garage door opener over 2 years ago, with holes drilled into it to make a hook) to slide between the window and house frame and snag the wire and pull it through.

I took the 22/4 wire, stripped off about 6" of outer insulation, and then cut the red and green wires off. Our scheme is "top cops"....that means black and white go on the top sash, which leaves "christmas" (red and green) on the bottom sash. So, I took the black and white wires, put them in the little loop, and pulled the green wire back out. It worked almost always, almost flawlessly. When I had to pull particularly hard, then I trimmed off the bent portion of wire. Then I stripped about 3/8" off the wires (I bought a new pair of wire strippers, with a 22 gauge hole...I was very pleased with how well they worked), twisted the strands together, inserted it in the sensor and tightened the screws.

Then I pushed it into the hole, making sure to keep the slack free. They hold very well just by friction, I didn't feel the need to glue it.

For the magnet, it fit in the channel on the top of the sash perfectly. I just put a spot of gorilla glue on the bottom and I was done....with the TOP sash.

For the bottom sash, I drilled the hole just below the pencil mark. The mark was made by tracing the top of the bottom sash, so I knew to not go any higher than that. It was a very small area to work with...the hole just barely fit below the mark and above the end of the plastic.

I did the same trick to get the wire out the hole, and then hooked up the sensor.

This one also pushed in and held in place nicely.

I'm pleased with how well concealed it ends up...with the window in place, you'd basically never see it.

For the magnet, I had to drill a small hole in the top of the sash. I wasn't using the same magnet that I used on the top sash...they were much too big. So I bought a bunch of smaller magnets. They were 3/8" diamater, but only 1/4" thick. So I just had to drill a 1/4" hole. However, again, the area to work with was small, and there was a small divot on that edge, so I had to make sure the drill didn't walk around. So, I made a guide out of a spare piece of wood and more of my handy garage-door-opener metal. Don't I have all the fancy tools??! A couple clamps to hold it on, and it worked just fine.

Another dab of gorilla glue, and the magnet is in. I bought the kind with the hole in the center in case I wanted to actually screw them in later, should the gorilla glue be found to be lacking.

So there ya go. They weren't as hard as I was terrified they'd be...and so far, from the testing, they work just great.

I think there's no hope at all of a concealed sensor, specifically on the lower sash. There's very little broad flat edge on any of them.

This is the bottom edge of the bottom sash:

The thickest smooth part is barely 3/8". Aren't the smallest concealed sensor magnets more than that? The other issue is that when the window is closed, there's still a decent gap between the bottom of the sash and the frame:

About 1/4". You can also see that the area where the contact sensor matching the magnet would go in the frame, and it looks like it might be even less than 3/8".

So, I considered the top part of the bottom sash...it has a thicker area (on the side of course, since nothing could be mounted on the top and be concealed).

So there appears to be plenty of room there for a small magnet. However....in the frame where that part of the sash would be, there's a bunch of fur-type stuff. Not exactly drilling heaven.

I'm not sure how I feel about trying to drill through that...the fur is probably there for a reason.

Now with the top sash, I have another delimna...there's absolutely NO place for a surface mount. Part of the reason is that when the bottom sash is opened all the way up, it leaves this:

I know it LOOKS like a gap, but in reality, it has completely covered the top sash. So any surface mounted anything will be cleanly scraped off everytime we open the bottom sash. I suppose I can artificially limit how far the bottom sash can open....

But maybe I won't have to...the top sash seems to have more and better potential for putting in a concealed sensor on the top. Here's the top of the sash:

Almost 3/4"!

And the top of the frame where that seats is about the same size (ladybug for scale...and because they're EVERYWHERE):

So I'm thinking at this point I'd probably have to go surface mount on the bottom sash and concealed on the top. I'd really rather go concealed on the bottom too.

Does anyone see any better option or something that might fit in these constraints and work well?

MUCH LATER....

Well, here is how I finally did it:

The circles indicate where the sensors and magnets were put. I drilled into the frame surrounding the window just below the middle of the window, where the sashes meet. In this pic, the bottom sash is unlatched and tilted out so I can work on it.

The first thing I did was the top sash because that's where the end of the wire was....on the 2nd floor, I had to do the bottom sash first. It didn't really matter.

First was the prep...

I needed to make sure that the magnet was lined up with where the sensor went, so I put a piece of tape on the sash at the spot the magnet was going to go, because that was kind of picky. Then I closed the sash, and put another piece of tape on the frame at the same spot. So, as long as I drill the hole right next to the tape into the frame, and then glue the magnet right next to the tape on the sash, then they'll certainly be close enough to work together.

I then drilled the hole using the 3/8" bit. The bit had a very sharp bit, so I can basically press it into the vinyl (they were vinyl clad wood windows) so that the bit didn't walk at all. Once the hole was drilled, I used a spare piece of wire, twisted into a little loop, and I pushed it up into the hole. I then took my specially made tool (it's a leftover piece of metal from when I installed our garage door opener over 2 years ago, with holes drilled into it to make a hook) to slide between the window and house frame and snag the wire and pull it through.

I took the 22/4 wire, stripped off about 6" of outer insulation, and then cut the red and green wires off. Our scheme is "top cops"....that means black and white go on the top sash, which leaves "christmas" (red and green) on the bottom sash. So, I took the black and white wires, put them in the little loop, and pulled the green wire back out. It worked almost always, almost flawlessly. When I had to pull particularly hard, then I trimmed off the bent portion of wire. Then I stripped about 3/8" off the wires (I bought a new pair of wire strippers, with a 22 gauge hole...I was very pleased with how well they worked), twisted the strands together, inserted it in the sensor and tightened the screws.

Then I pushed it into the hole, making sure to keep the slack free. They hold very well just by friction, I didn't feel the need to glue it.

For the magnet, it fit in the channel on the top of the sash perfectly. I just put a spot of gorilla glue on the bottom and I was done....with the TOP sash.

For the bottom sash, I drilled the hole just below the pencil mark. The mark was made by tracing the top of the bottom sash, so I knew to not go any higher than that. It was a very small area to work with...the hole just barely fit below the mark and above the end of the plastic.

I did the same trick to get the wire out the hole, and then hooked up the sensor.

This one also pushed in and held in place nicely.

I'm pleased with how well concealed it ends up...with the window in place, you'd basically never see it.

For the magnet, I had to drill a small hole in the top of the sash. I wasn't using the same magnet that I used on the top sash...they were much too big. So I bought a bunch of smaller magnets. They were 3/8" diamater, but only 1/4" thick. So I just had to drill a 1/4" hole. However, again, the area to work with was small, and there was a small divot on that edge, so I had to make sure the drill didn't walk around. So, I made a guide out of a spare piece of wood and more of my handy garage-door-opener metal. Don't I have all the fancy tools??! A couple clamps to hold it on, and it worked just fine.

Another dab of gorilla glue, and the magnet is in. I bought the kind with the hole in the center in case I wanted to actually screw them in later, should the gorilla glue be found to be lacking.

So there ya go. They weren't as hard as I was terrified they'd be...and so far, from the testing, they work just great.