sda

Active Member

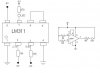

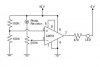

I'm trying to put together a sample circuit with an LM311 to make sure I understand how it works.

From what I do understand, which seems to be wrong, is that pin 7 is an open collector.

When pin 2 voltage (input+) is less than pin 3 voltage (input-), conditions are met and pin 1 (emit out) is connected to pin 7 (col out),

in this case ground, and the LED should turn on. It doesn't. But if I connect pin 2 directly to ground, 0V, the LED will turn on.

What am I doing wrong? Probably everything!

From what I do understand, which seems to be wrong, is that pin 7 is an open collector.

When pin 2 voltage (input+) is less than pin 3 voltage (input-), conditions are met and pin 1 (emit out) is connected to pin 7 (col out),

in this case ground, and the LED should turn on. It doesn't. But if I connect pin 2 directly to ground, 0V, the LED will turn on.

What am I doing wrong? Probably everything!